Page 20 - 3D Metal Printing Summer 2016

P. 20

3D FEATURE

Five Things Manufacturers

Need to Know About

3DMP

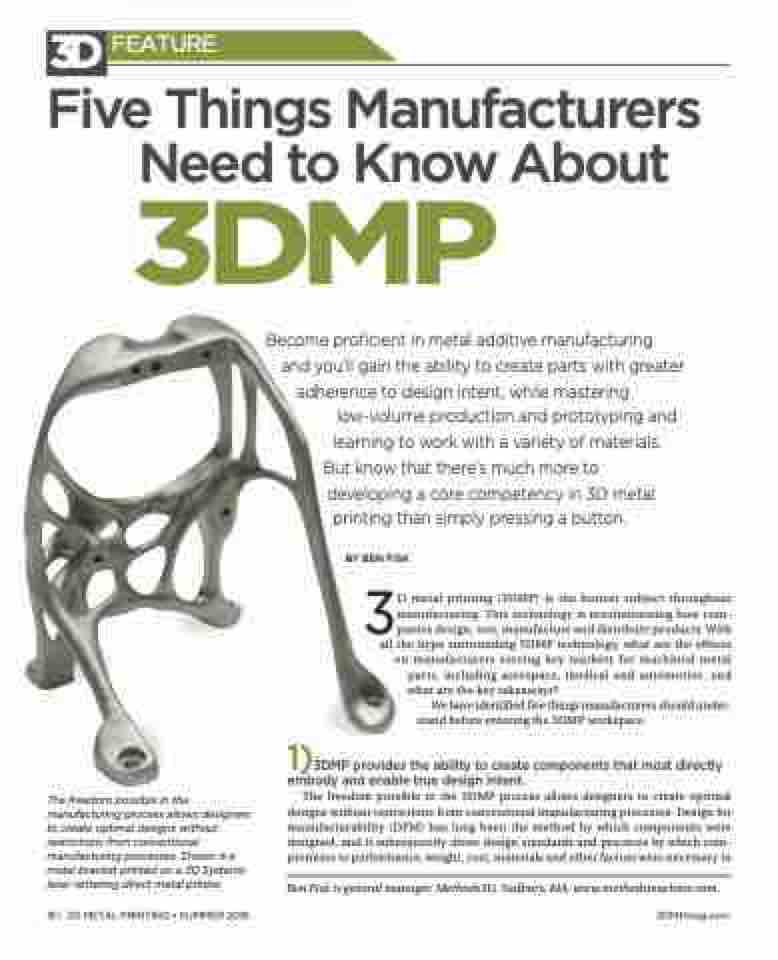

The freedom possible in the manufacturing process allows designers to create optimal designs without restrictions from conventional manufacturing processes. Shown is a metal bracket printed on a 3D Systems laser-sintering direct metal printer.

Become proficient in metal additive manufacturing and you’ll gain the ability to create parts with greater

adherence to design intent, while mastering low-volume production and prototyping and

learning to work with a variety of materials. But know that there’s much more to

developing a core competency in 3D metal printing than simply pressing a button.

BY BEN FISK

3D metal printing (3DMP) is the hottest subject throughout manufacturing. This technology is revolutionizing how com- panies design, test, manufacture and distribute products. With

all the hype surrounding 3DMP technology, what are the effects on manufacturers serving key markets for machined metal parts, including aerospace, medical and automotive, and

what are the key takeaways?

We have identified five things manufacturers should under-

stand before entering the 3DMP workspace.

1)3DMP provides the ability to create components that most directly embody and enable true design intent.

The freedom possible in the 3DMP process allows designers to create optimal designs without restrictions from conventional manufacturing processes. Design for manufacturability (DFM) has long been the method by which components were designed, and it subsequently drove design standards and practices by which com- promises to performance, weight, cost, materials and other factors were necessary to

Ben Fisk is general manager, Methods3D, Sudbury, MA; www.methodsmachine.com.

18 | 3D METAL PRINTING • SUMMER 2016

3DMPmag.com